- Home

- About Us

-

Products

Automation Components

- MCB, MCCB, Contactors

- Thermal Overload Relays, MPCB, Motor Starters, Changeover Switches

- HRC Fuses, Capacitors, Meters, Distribution Boards

- AC/DC Drives, Power Supplies, SMPS, Hour Meters & Counters

- PLC Controllers, HMI, Alarm Annunciators, PID & Temperature Controllers

- Proximity Sensors & many more.

Electrical Supplies

Pneumatics & Instruments

Industrial Engineering Components

- Brands

- Services

- Gallery

- Contact

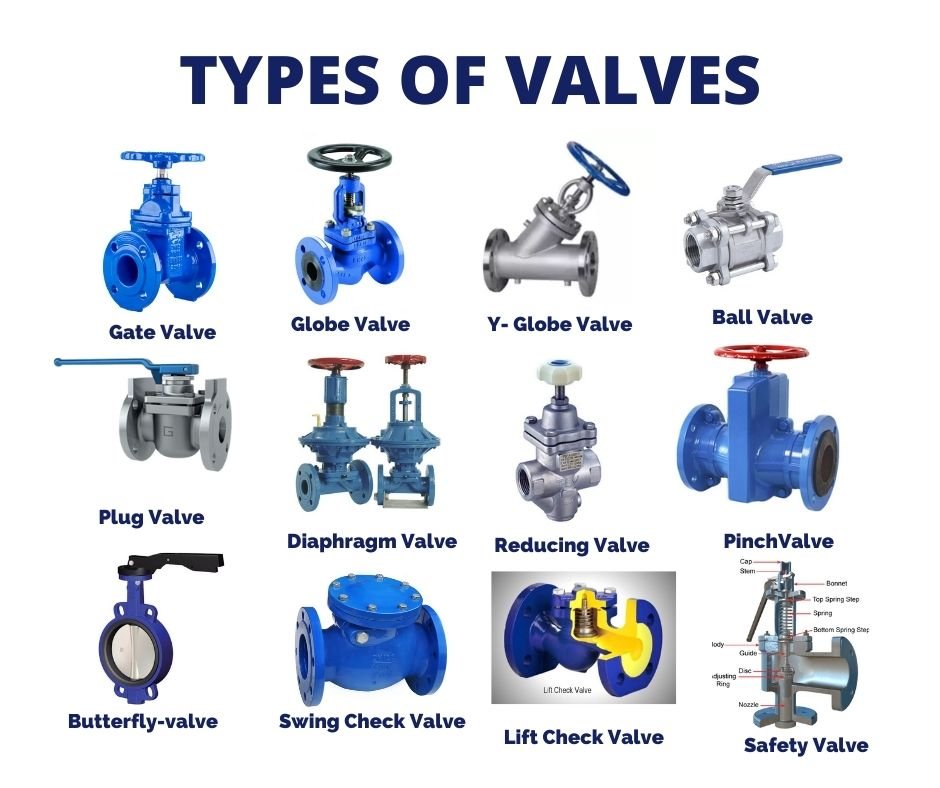

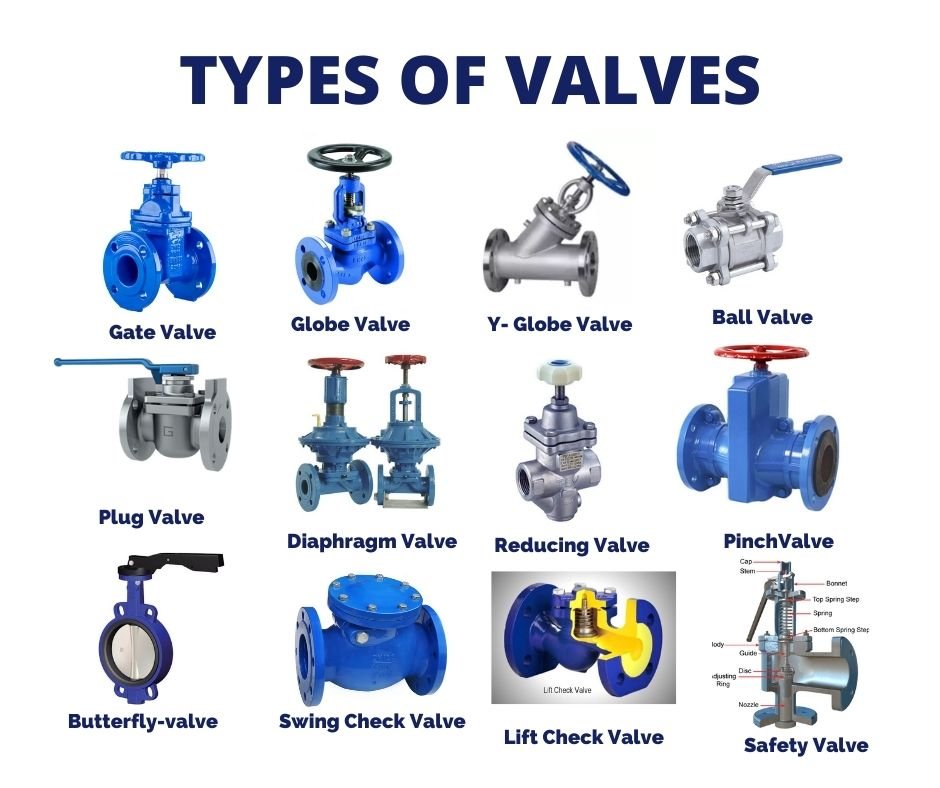

Industrial Valves

Complete range of industrial valves for fluid control and isolation applications

Complete range of industrial valves for various applications

Industrial Valves Overview

Fluid Control

Valves Fundamentals:

- Isolation Valves: Used to completely stop fluid flow (Ball, Gate, Plug valves)

- Regulation Valves: Used to control flow rate (Globe, Needle, Control valves)

- Check Valves: Prevent backflow in pipelines (Non-Return Valves)

- Strainers: Protect equipment by filtering debris from fluid streams

Valve Type Comparison:

| Valve Type | Primary Function | Operation | Pressure Range | Size Range | Best For |

|---|---|---|---|---|---|

| Ball Valve | Isolation | Quarter-turn | PN16 - PN100 | ½" - 24" | Quick on/off, general purpose |

| Butterfly Valve | Isolation/Regulation | Quarter-turn | PN10 - PN40 | 1½" - 60" | Large diameters, space saving |

| Gate Valve | Isolation | Multi-turn | PN10 - PN250 | 2" - 60" | Full flow, low pressure drop |

| Globe Valve | Regulation | Multi-turn | PN16 - PN100 | ½" - 12" | Precise flow control |

| Check Valve | Backflow prevention | Automatic | PN10 - PN40 | ½" - 48" | Pump protection, pipeline safety |

Ball Valves

General IndustrialBall Valve Features & Specifications:

- Type: 2-Way / 3-Way Ball Valve

- Sizes: ½″ – 24″ (DN15 – DN600)

- Materials: SS304/316, WCB, Cast Iron

- Pressure Ratings: PN16, PN25, ANSI 150/300/600

- Seat: PTFE / RPTFE / PPL

- Operation: Manual lever / Gear / Pneumatic / Electric

- Sealing: Metal or soft seated

- Uses: On/Off isolation for water, gas, oil

Full bore & reduced bore options available. Quick quarter-turn operation with bubble-tight shutoff.

Ball Valve Types

- Floating Ball Valves

- Trunnion Mounted Ball Valves

- Full Port Ball Valves

- Reduced Port Ball Valves

- 3-Way & Multi-port Ball Valves

- Fire Safe Ball Valves

Butterfly Valves

Space EfficientButterfly Valve Features & Specifications:

- Sizes: 1½″ – 24″ (DN40 – DN600)

- Standards: BS EN 593 / ISO 10631 / API 609

- Body Materials: Cast Iron, Ductile Iron, Stainless Steel

- Disc: SS / Ductile Iron

- Seat: EPDM / NBR / PTFE

- Connections: Wafer / Lug / Flanged

- Pressure: PN10 – PN40, ANSI 150

- Operation: Manual / Gear / Pneumatic / Electric

Good for large diameter isolation and flow control. Compact design saves space compared to gate valves.

Butterfly Valve Advantages

- Compact & Lightweight

- Quick Operation (Quarter-turn)

- Low Pressure Drop

- Good for Large Sizes

- Cost Effective

- Bi-directional Flow

Wafer Type

- Design: Fits between flanges

- Weight: Lightest option

- Cost: Most economical

- Use: Between ANSI flanges

Lug Type

- Design: Threaded inserts for bolts

- Weight: Medium weight

- Installation: Can be end-of-line

- Use: Dead-end service

Flanged Type

- Design: Integral flanges

- Weight: Heaviest option

- Pressure: Higher pressure rating

- Use: High pressure services

Plug Valves

Abrasive ServicePlug Valve Features & Specifications:

- Sizes: ½″ – 12″ (varies by manufacturer)

- Materials: Cast Steel, Stainless Steel, Bronze

- Pressure: PN16 – PN40 / ANSI 150 – 300

- Construction: Lubricated / Non-Lubricated

- Operation: Quarter-Turn Manual/Pneumatic

- Use: Abrasive/slurry services, on/off duty

- Design: Simple quarter-turn action

- Plug Type: Tapered/Cylindrical plug

Simple quarter-turn action with tapered/cylindrical plug. Excellent for abrasive fluids and slurry applications.

Plug Valve Types

- Lubricated Plug Valves

- Non-Lubricated Plug Valves

- Eccentric Plug Valves

- Multiport Plug Valves

- Expanding Plug Valves

- Jacketed Plug Valves

Globe Valves

Precise RegulationGlobe Valve Features & Specifications:

- Sizes: ½″ – 12″+

- Pressure: ANSI 150 / 300 / 600 (or PN 16/40)

- Body: Cast Steel, Stainless Steel

- End: Flanged / Threaded / Weld

- Seat Type: Globe/Angle/Y pattern

- Operation: Manual / Pneumatic / Electric

- Use: Flow regulation & throttling

- Characteristic: Linear flow characteristic

Excellent control valve choice due to linear characteristic. Good for precise throttling applications.

Globe Valve Types

- Standard Globe Valves

- Angle Globe Valves

- Y-Type Globe Valves

- Bellows Seal Globe Valves

- Control Globe Valves

- Cryogenic Globe Valves

Flow Characteristics

- Linear: Flow directly proportional to lift

- Equal Percentage: Exponential flow increase

- Quick Opening: High initial flow rate

- Modified Parabolic: Compromise between linear & EQ%

Trim Options

- Standard Trim: For general services

- Anti-Cavitation Trim: For high pressure drop

- Low Noise Trim: For noise reduction

- Abrasion Resistant Trim: For slurry services

Needle Valves

Fine ControlNeedle Valve Features & Specifications:

- Sizes: ¼″ – 1″ (DN6 – DN25)

- Materials: SS304 / SS316

- Pressure: 1000 / 3000 / 6000 psi (instrument versions)

- Ends: Threaded / Flange

- Use: Fine flow control / instrumentation

- Design: Tapered stem for precise metering

- Accuracy: Very fine control capability

- Applications: Instrumentation, sampling, gauges

Precise metering due to tapered stem design. Excellent for instrumentation and sampling applications.

Needle Valve Applications

- Pressure Gauges

- Flow Meters

- Sampling Systems

- Analytical Instruments

- Hydraulic Systems

- Pneumatic Systems

Gate Valves

Full FlowGate Valve Features & Specifications:

- Sizes: 4″ – 60″ (DN100 – DN1500)

- Pressure: ANSI 150 – 2500# / PN 10–40

- Material: Carbon Steel, Stainless Steel, Alloy

- End: Flanged / BW / RTJ / Thread

- Seal: Wedge / Parallel gate

- Operation: Handwheel / Gear / Actuated

- Use: Isolation in pipeline systems

- Advantage: Low pressure drop when fully open

Best for fully open/close with low ΔP. Not recommended for throttling or regulating flow.

Gate Valve Types

- Rising Stem Gate Valves

- Non-Rising Stem Gate Valves

- Wedge Gate Valves

- Parallel Slide Gate Valves

- Knife Gate Valves

- Through Conduit Gate Valves

Gate Valve Advantages

- Full bore design = low pressure drop

- Bi-directional flow capability

- Good for viscous fluids

- Simple design & maintenance

- Available in large sizes

Gate Valve Limitations

- Not suitable for throttling

- Slower operation than quarter-turn

- Potential for seat erosion

- Large space requirement

- Heavy weight

Check Valves (NRV)

Backflow PreventionCheck Valve Features & Specifications:

- Types: Swing / Lift / Wafer / Spring

- Sizes: DN15 – DN600+

- Materials: Cast Steel, SS, Bronze

- Pressure: PN16 – PN40, ANSI Classes

- End: Wafer / Flanged / Threaded

- Use: Prevent backflow in piping

- Operation: Automatic (no external power)

- Selection: Based on flow conditions

Available in multiple internal styles based on application. Essential for pump protection and pipeline safety.

Check Valve Applications

- Pump Discharge Lines

- Compressor Systems

- Boiler Feed Lines

- Steam Lines

- Water Distribution

- Chemical Processes

Swing Check

- Design: Hinged disc

- Flow: Full port

- Use: Horizontal pipes

- Sizes: 2" and larger

Lift Check

- Design: Piston/ball lift

- Flow: Reduced port

- Use: Any orientation

- Sizes: Small to medium

Wafer Check

- Design: Dual disc

- Flow: Full port

- Use: Space saving

- Sizes: 2" - 24"

Spring Check

- Design: Spring assisted

- Flow: Any orientation

- Use: Fast closing

- Sizes: All sizes

Y-Type Strainers

Pipeline ProtectionY-Type Strainer Features & Specifications:

- Sizes: ½″ – 24″ (DN15 – DN600)

- Pressure: PN10 / PN16 / PN40 / ANSI 150 – 600

- Materials: Cast Iron, CS (WCB), SS304/316

- Screen: SS Perforated Mesh (40/60/100 mesh)

- Connections: Screwed / Flanged

- Use: Filter debris from liquids/steam/gas

- Design: Y-shaped body for easy cleaning

- Installation: Horizontal with basket down

Essential for protecting pumps, valves, and instruments from pipeline debris. Easy to clean without removing from line.

Protection Applications

- Pump Inlet Protection

- Control Valve Protection

- Flow Meter Protection

- Spray Nozzle Protection

- Steam Trap Protection

- Heat Exchanger Protection

Screen Mesh Details

| Mesh Size | Hole Size (mm) | Application |

|---|---|---|

| 10 mesh | 2.00 | Coarse debris |

| 20 mesh | 0.85 | General purpose |

| 40 mesh | 0.42 | Fine protection |

| 60 mesh | 0.25 | Very fine particles |

| 100 mesh | 0.15 | Instrument protection |

Selection Guidelines

- Screen Area: Should be 2-3 times pipe area

- Pressure Drop: Max 0.5 bar when clean

- Cleaning: Consider blow-down valve

- Installation: Basket should point down

- Material: Match pipeline material

- Bypass: Recommended for critical services

Valve Selection Guide

Key Selection Parameters:

- Fluid Type: Water, Steam, Gas, Oil, Chemicals, Slurry

- Temperature Range: Cryogenic to High Temperature

- Pressure Rating: Vacuum to High Pressure

- Size Requirements: Pipe size and flow capacity

- Operation: Manual, Automated, Frequency of operation

Special Considerations:

- Leakage Class: ANSI/FCI 70-2 standards

- Fire Safe: API 607/6FA certification

- Cryogenic Service: Extended bonnet design

- Sanitary/Hygienic: Smooth surfaces, CIP/SIP

- Noise/Vibration: Anti-cavitation trim

Valve Selection Matrix:

| Application | Recommended Valve | Key Features Required | Typical Materials | Actuation |

|---|---|---|---|---|

| Water Distribution | Gate Valve, Butterfly Valve | Full bore, Low pressure drop | Cast Iron, Ductile Iron | Manual, Gear, Electric |

| Steam Service | Globe Valve, Gate Valve | High temperature, Pressure rating | Cast Steel, Alloy Steel | Manual, Pneumatic |

| Chemical Process | Ball Valve, Diaphragm Valve | Corrosion resistant, Leak tight | SS316, Hastelloy, PTFE lined | Pneumatic, Electric |

| Oil & Gas Pipeline | Ball Valve, Gate Valve | Fire safe, High pressure | Carbon Steel, Duplex SS | Manual, Hydraulic, Gas over Oil |

| Slurry/Solid Handling | Knife Gate Valve, Plug Valve | Abrasion resistant, Full bore | SS316, Hard faced, Rubber lined | Manual, Pneumatic |

| HVAC Systems | Butterfly Valve, Ball Valve | Compact, Light weight | Carbon Steel, Bronze | Manual, Pneumatic |

| Instrumentation | Needle Valve, Ball Valve | Fine control, Leak proof | SS316, Brass | Manual |

| Pharmaceutical | Diaphragm Valve, Ball Valve | Sanitary, CIP/SIP capable | SS316L, Electropolished | Manual, Pneumatic |

Industrial Valves Comparison

| Valve Type | Primary Function | Operation Type | Pressure Drop | Throttling Capability | Cost Factor | Maintenance Level |

|---|---|---|---|---|---|---|

| Ball Valve | On/Off Isolation | Quarter-turn | Very Low | Poor (not recommended) | Medium | Low |

| Butterfly Valve | Isolation & Regulation | Quarter-turn | Low | Good (0-60° open) | Low | Low-Medium |

| Gate Valve | Isolation Only | Multi-turn | Very Low | Poor (damages seat) | Medium-High | Medium |

| Globe Valve | Regulation & Isolation | Multi-turn | High | Excellent | High | Medium-High |

| Plug Valve | Isolation | Quarter-turn | Low | Fair | Medium | Medium |

| Check Valve | Backflow Prevention | Automatic | Medium | N/A (auto only) | Low-Medium | Low |

Technical Support & Contact

Complete Process Control Solutions

We provide comprehensive process control products including positioners, actuators, valves, and instrumentation for various industrial applications.

Control Devices

- Valve positioners (Rotork, Rotex)

- Pneumatic & electric actuators

- Control valves & accessories

- Process instrumentation

Technical Services

- System design and sizing

- Installation and commissioning

- Calibration and setup

- Maintenance and repair

Support Services

- Product selection assistance

- Technical documentation

- Spare parts supply

- Training programs